The ceramic fiber thermal insulation renovation design of the insulation boxes in steel ingots’ (slab (steel ingot)) hot delivery automobiles

Introduction of insulation boxes in ingots' (slab (steel ingot)) hot delivery automobiles:

Due to the cumbersome production process of metallurgical enterprises, the transportation of slabs (steel ingots) between slab (steel ingot) smelting and rolling forming processes largely restricts production costs. In order to reduce energy consumption to a greater extent and achieve the goal of reducing production costs, most metallurgical production enterprises use slab (steel ingot) hot delivery (also known as slab or steel ingot red-hot delivery) vehicles. Under such conditions, the heat preservation of the transport box have become a very important issue.

The process requirements for the lining structure of the general automobile transportation insulation box mainly include the following aspects: first, long-term work under the high temperature of 1000 ℃, good insulation performance, and excellent thermal shock resistance should be ensured; secondly, the loading and unloading of hot slabs (steel ingots) hoisting should be convenient, which can withstand vibrations, impacts, bumps; and lastly, the insulation boxes must have a light structure, a long service life, and a low cost.

Disadvantages of traditional light brick lining: light bricks have poor thermal shock resistance, and are prone to burst damage during long-term vibrations, impacts, and bumps.

The development and the improvement of ceramic fiber technology provide a reliable basis for the design of automobile insulation boxes. CCEWOOL ceramic fiber is light, flexible, resistant to high temperatures and thermal fatigue, and can absorb vibration. As long as the structure design is reasonable, the construction quality can be obtained, and the above process requirements can be fully met. Therefore, the use of CCEWOOL ceramic fiber as the lining structure of the insulation boxes is the best choice for this type of insulation boxes.

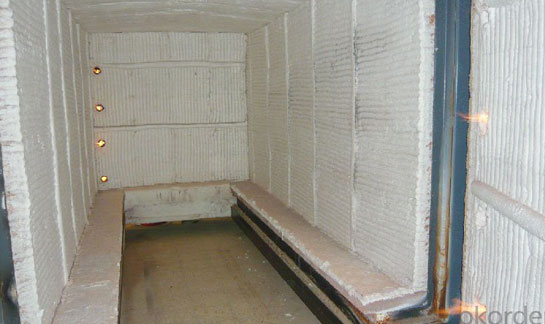

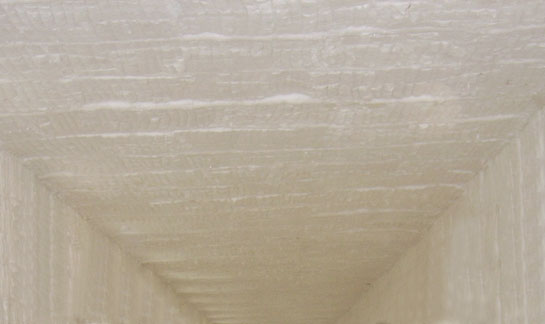

Introduction to the full-fiber lining structure of slab (steel ingot) hot delivery automobile insulation boxes

The specifications of the insulation boxes are mainly 40 tons and 15 tons, and the structure of the insulation box for a 40-ton trailer is 6000 mm long, 3248 mm wide, and 2000 mm high. The bottom of the box lining structure is CCEFIRE clay brick lining, with CCEWOOL standard ceramic fiber modules which are arranged in sequence along the folding direction on the walls and the top cover. Compensation bars are added between each row to compensate for the linear shrinkage of modules under high temperatures. The module anchoring structure is in the form of nail anchoring.

Application effects

The test run of this structure shows that the demolding temperature of the steel ingot is 900-950℃, the temperature of the steel ingot after loading is about 850℃, and the temperature of the steel ingot after unloading is 700-800℃. Between demolding the steel ingot and the delivery to the forging workshop is 3 kilometers, and the hot delivery takes about 1.5-2 hours, during which 0.5-0.7 hours for loading, 0.5-0.7 hours on the way and 0.5-0.7 hours for unloading. The ambient temperature is 14℃, the temperature inside the box is about 800℃, and the surface temperature of the top cover is 20℃, so the heat preservation effect is good.

1. The insulation vehicle is mobile, flexible, effective in insulation, and widely adaptable, so it is very worthy of promotion and used in the case of inconvenient railway transportation.

2. The full-fiber thermal insulation box and red-hot delivery steel ingot (slab (steel ingot)) are successful because of its compact structure, light weight, good thermal insulation performance, and significant energy saving effects.

3. To ensure the quality of ceramic fiber products is important to construction quality, and the lining structure must be compact and dense during construction.

In short, the red-hot delivery of steel ingots (slabs (steel ingots)) by the automobile insulation box is an effective and important way to save energy.

Post time: May-10-2021