CCEWOOL ceramic fiber provides high-efficiency energy-saving designs for the heat insulation of furnaces in the metallurgical industry to reduce energy consumption, which has saved a lot of costs for our customers in this industry.

Common Applications:

Insulation layer on furnace top

Lining for furnace walls

Inlet and outlet on furnace walls

Lining for flue mouth and overhaul door

Insulation for burner area

Insulation for furnace bottom

Regenerator walls

Temperature measurement hole of regenerator and furnace body

Suction measuring pipe of regenerator and furnace body

Expansion joints on regenerator walls

Hot air pipe insulation

Exhaust flue insulation

Furnace cover, furnace walls

Outlet gate

-

Continuous Hot-dip Galvanizing Annealing for Strip Steel

View More -

Coke Ovens

View More -

Bell-type Furnaces

View More -

Annular Heating Furnace Renovation

View More -

Roller Hearth Soaking Furnaces for Continuous Casting

View More -

Walking-type Heating

View More -

Trolley Furnaces

View More -

Soaking Furnaces

View More -

Pushing Steel Continuous Heating Furnace

View More

-

Ceramic Bulk Fiber

View More -

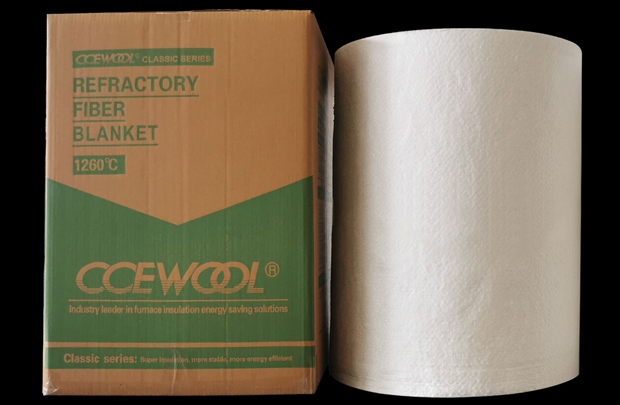

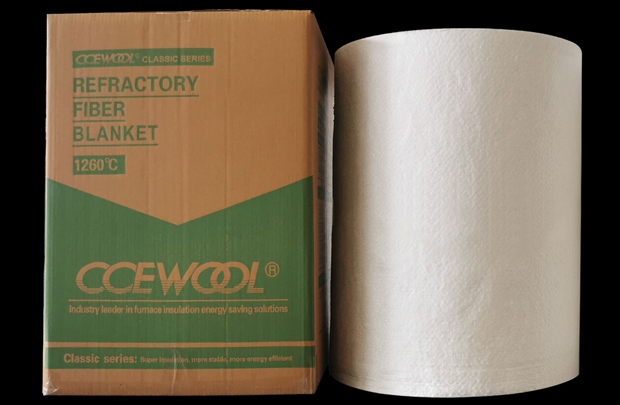

Ceramic Fiber Blanket

View More -

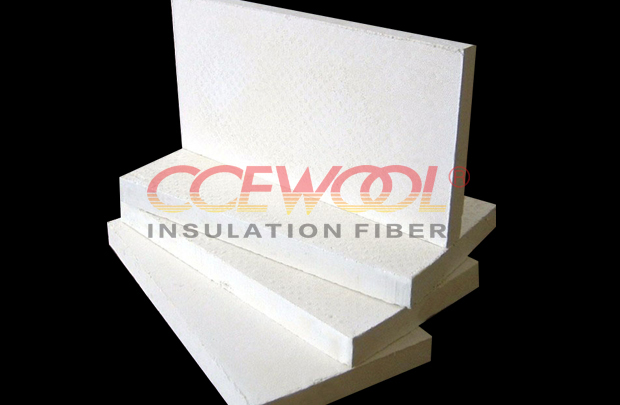

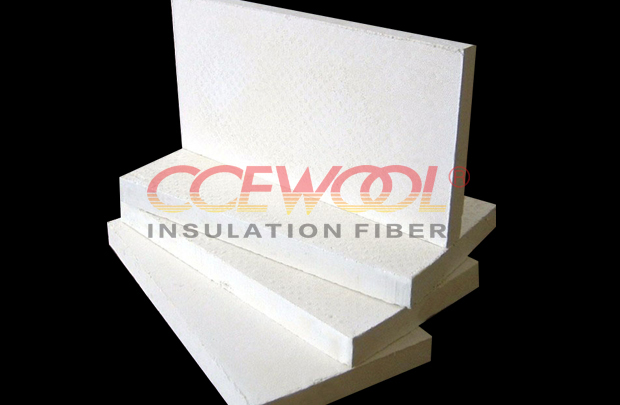

Ceramic Fiber Board

View More -

Ceramic Fiber Paper

View More -

Ceramic Fiber Module

View More -

Ceramic Fiber Yarn

View More -

Ceramic Fiber Tape

View More -

Ceramic Fiber Rope

View More -

Ceramic Fiber Cloth

View More -

Vacuum Formed Ceramic Fiber

View More -

1000℃ Calcium Silicate Board

View More -

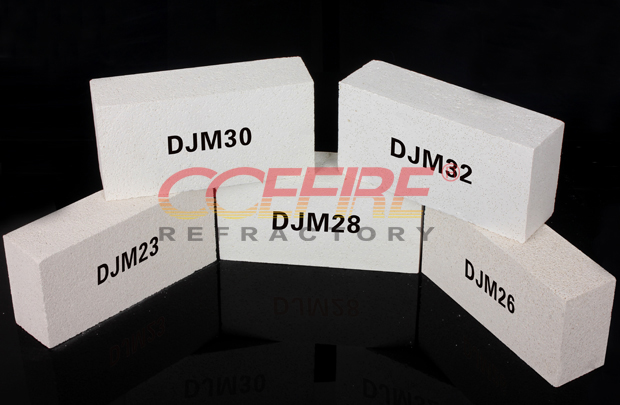

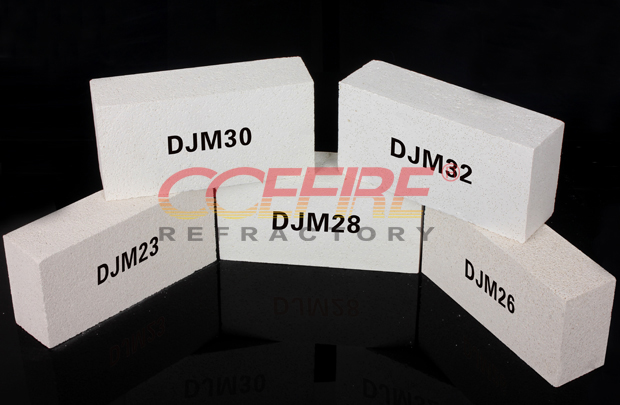

DJM Series Insulating Fire Brick

View More -

DCHA Series Fire Brick

View More -

Refractory Castable

View More -

DEHA Series High Alumina Refractory Brick

View More