CCEWOOL® inorganic ceramic fiber board is produced with high purity ceramic fiber bulk, which has super low shot content, as raw material. And is produced through self developed production lines, adding inorganic binders. And the inorganic ceramic fiber board is formed. CCEWOOL® inorganic ceramic fiber board does not contain organic matter, and is smokeless and odorless under high temperature. It is the most ideal environmentally friendly high temperature heat insulation board for household wall-hung boilers, electric stoves, ovens, etc.

Strict control of raw materials

Control impurity content, ensure low thermal shrinkage, and improve heat resistance

1. CCEWOOL ceramic fiber boards use high-purity ceramic fiber cotton as the raw material.

2. Controlling the content of impurities is an important step to ensure the heat resistance of ceramic fibers. High impurity content can cause the coarsening of crystal grains and the increase of linear shrinkage, which is the key reason for the deterioration of fiber performance and the reduction of its service life.

3. Through strict control at each step, we reduce the impurity content of the raw materials to less than 1%. The CCEWOOL ceramic fiber boards we produce are pure white, and the linear shrinkage rate is lower than 2% at the hot surface temperature of 1200°C. The quality is more stable, and the service life is longer.

Production process control

Reduce the content of slag balls, ensure low thermal conductivity, and improve thermal insulation performance

1.CCEWOOL inorganic ceramic fiber board is produced with high purity ceramic fiber bulk, which has super low shot content, as raw material. And is produced through self developed production lines, adding inorganic binders. And the inorganic ceramic fiber board is formed.

2. Thickness of CCEWOOL new type inorganic ceramic fiber board can be above 100mm. As it is produced with inorganic binder, the CCEWOOL inorganic ceramic fiber board doesn’t contain organic matter.

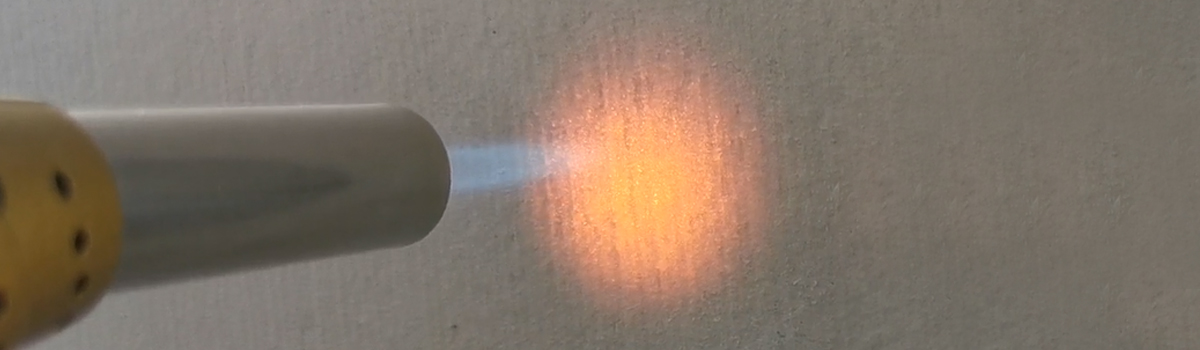

3. It is smokeless, odorless, and does not change color when being exposed to open flame or high temperature. And its strength and hardness will increase instead of decrease under high temperature.

Quality control

Ensure bulk density and improve thermal insulation performance

1. Each shipment has a dedicated quality inspector, and a test report is provided prior to the departure of products from the factory to ensure the export quality of each shipment of CCEWOOL.

2. A third-party inspection (such as SGS, BV, etc.) is accepted.

3. Production is strictly in accordance with ISO9000 quality management system certification.

4. Products are weighed before packaging to ensure that the actual weight of a single roll is greater than the theoretical weight.

5. The outer packaging of each carton is made of five layers of kraft paper, and the inner packaging is a plastic bag, suitable for long-distance transportation.

High chemical purity in products:

The content of high-temperature oxides, such as Al2O3 and SiO2, reaches 97-99%, thus ensuring the heat resistance of products. The maximum operational temperature of CCEWOOL ceramic fiberboard can reach 1600 °C at the temperature grade of 1260-1600 °C.

CCEWOOL ceramic fiber boards can not only replace calcium silicate boards as the backing material of furnace walls, but also can be directly used on the hot surface of furnace walls, giving which excellent wind erosion resistance.

Low thermal conductivity and good thermal insulation effects:

Compared with traditional diatomaceous earth bricks, calcium silicate boards and other composite silicate backing materials, CCEWOOL ceramic fiber boards have lower thermal conductivity, better thermal insulation, and more significant energy saving effects.

High strength and easy to use:

The compressive strength and flexural strength of CCEWOOL ceramic fiberboards are both higher than 0.5MPa, and they are a non-brittle material, so they fully meet the requirements of hard backing materials. They can completely replace blankets, felts, and other backing materials of the same kind in insulation projects with high strength requirements.

CCEWOOL ceramic fiberboards’ accurate geometric dimensions allow them to be cut and processed at will, and the construction is very convenient. They have solved the problems of brittleness, fragility, and high construction damage rate of calcium silicate boards and greatly shorten the construction period and reduce the construction costs.

-

Peru Customer

1260HP Ceramic Fiber Bulk - CCEWOOL®

Cooperation years: 11 years

Product size: 20kg/bag25-07-09 -

Italian customer

1260℃ Ceramic Fiber Bulk - CCEWOOL®

Cooperation years: 2 years

Product size: 20kg/bag25-06-25 -

Polish Customer

Thermal Insulation Blanket - CCEWOOL®

Cooperation years: 6 years

Product size: 19×610×9760mm/ 50×610×3810mm25-04-30 -

Spanish Customer

Ceramic Fiber Insulation Roll - CCEWOOL®

Cooperation years: 7 years

Product size: 25×940×7320mm/ 25×280×7320mm25-04-23 -

Peruvian Customer

Refractory Ceramic Fiber Blanket - CCEWOOL®

Cooperation years: 6 years

Product size: 25×610×7620mm/ 50×610×3810mm25-04-16 -

Guatemalan Customer

Refractory Insulation Blanket - CCEWOOL®

Cooperation years: 7 years

Product size: 25×610×7620mm/ 38×610×5080mm/ 50×610×3810mm25-04-09 -

Singapore Customer

Refractory Ceramic Fiber Blanket - CCEWOOL®

Cooperation years: 3 years

Product size: 10x1100x15000mm25-04-02 -

Guatemala Customers

High Temp Ceramic Fiber Block - CCEWOOL®

Cooperation years: 7 years

Product size: 250x300x300mm25-03-26