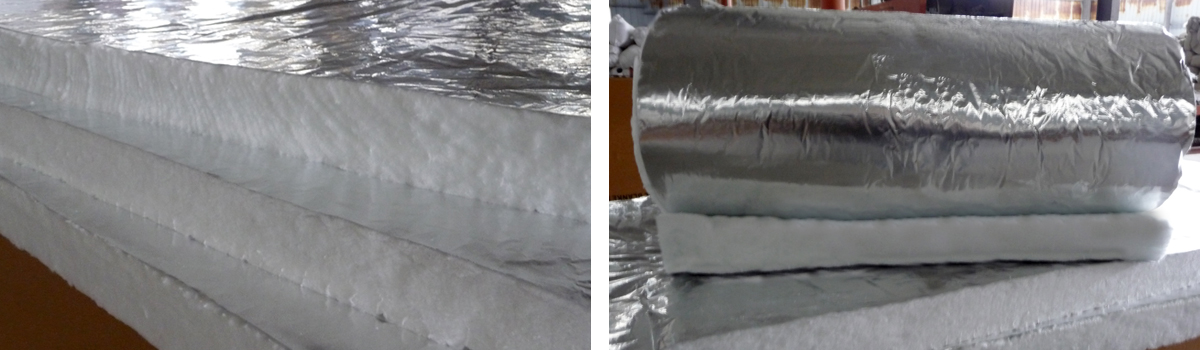

CCEWOOL® research series Ceramic Fiber Blanket with Aluminum Foil is mainly used for insulation and fire resistant application in fire protection pipe, flue and vessel.

Adopting European standard aluminum foil, the aluminum foil is thin and has good conformability. Being directly bond without using binders can connect the CCEWOOL® ceramic fiber blanket with the aluminum foil better. This product is easy to install and more durable.