Temperature degree: 1260℃ (2300℉), 1400℃ (2550℉), 1430℃(2600℉)

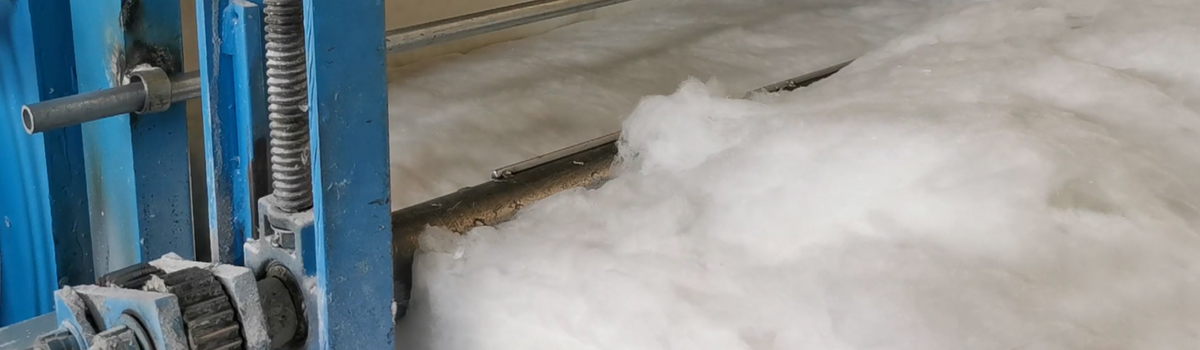

CCEWOOL® Research Series Ceramic Bulk Fiber for Textile is made from standard ceramic fiber bulk through a further shot-removal process to deliver uniform diameter and high spinnability of fiber cotton, which is one of ideal raw material for the production of textiles.