In high-temperature engineering, “ceramic bulk” is no longer just a generic filler. It has become a critical component that influences system sealing, insulation performance, and operational reliability. A truly high-quality ceramic bulk must combine strong structural adaptability with the ability to support long-term thermal system stability.

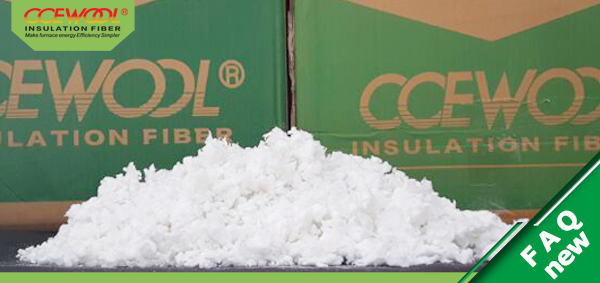

CCEWOOL® Chopped Ceramic Fiber Bulk was developed in response to these evolving demands, offering a reliable solution for high-performance industrial applications.

Precision Chopping for Superior Structure

CCEWOOL® Chopped Ceramic Fiber Bulk is produced through automated chopping of high-purity ceramic wool fiber. The result is consistent fiber length and uniform granule distribution, ensuring stable packing density.

In pressing or vacuum forming processes, this uniformity delivers tighter fiber distribution, enhanced bonding strength, and improved structural integrity. In practice, it leads to clearer molded profiles, cleaner edges, lower thermal shrinkage, and reduced deformation under high temperatures.

Low Thermal Mass + Thermal Shock Resistance

By optimizing the ratio of alumina and silica, CCEWOOL® RCF Bulk achieves a combination of low thermal conductivity and high thermal stability. Its uniform fiber structure and stable microporosity help suppress thermal stress transfer in continuous operations at 1100–1430°C.Once applied in high-temperature equipment, it delivers more durable sealing, extended structural lifespan, reduced thermal losses, and improved energy efficiency and operational reliability.

From material preparation and performance control to field performance, CCEWOOL® Chopped Ceramic Fiber Bulk is not just a form of ceramic bulk—it is a solution that delivers both structural sealing and thermal efficiency improvements for industrial systems.

Post time: Jun-30-2025