This issue we will continue to introduce installation method of insulation ceramic module.

1. Installation process of insulation ceramic module

1) Mark the steel plate of the furnace steel structure, determine the position of the welding fixing bolt, and then weld the fixing bolt.

2) Two layers of fiber blanket shall be laid in staggered way on the steel plate and fixed with clip cards. The total thickness of the two layers of fiber blanket is 50mm.

3) Use the guide rod to align the central hole of the fiber module with the fixing bolt, and lift the insulation ceramic module so that the central hole of the module is embedded in the fixing bolt.

4) Use a special wrench to screw the nut on the fixing bolt through the central hole sleeve, and tighten it to fix the fiber module firmly. Install the fiber modules in sequence.

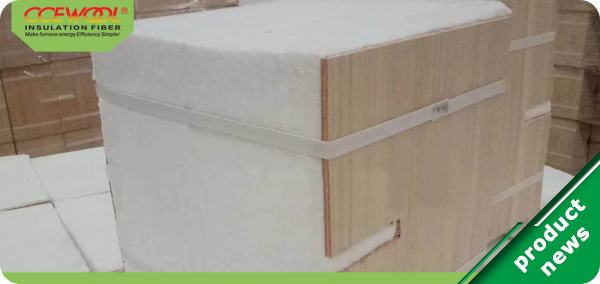

5) After installation, remove the plastic packaging film, cut the binding belt, pull out the guide tube and the plywood protective sheet, and trim.

6) If it is necessary to spray high-temperature coating on the fiber surface, a layer of curing agent shall be sprayed first, and then high-temperature coating shall be sprayed.

Next issue we will continue to introduce installation method of insulation ceramic module.Please stay tuned!

Post time: Mar-08-2023