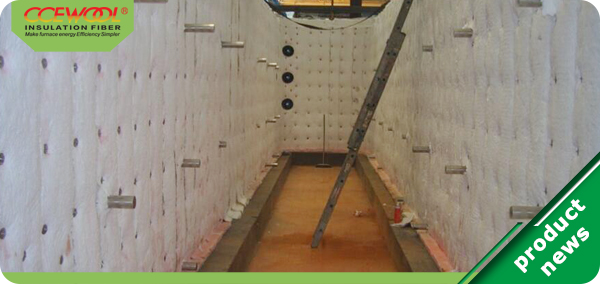

2. Specific implementation process of insulation ceramic fiber furnace lining construction:

(1) Scribing: Determine the midpoint position of the components according to the drawings to ensure that the requirements are met, and complete the scribing step with a reliable method;

(2) Welding: after the anchor midpoint is determined, it shall be accurately welded. After the position is determined, full welding shall be carried out; Besides the material of the anchor, the size and thickness of the anchor also affects high temperature strength of the anchor.

(3) Laying auxiliary materials for insulation ceramic fiber blanket: the auxiliary materials in turn include: backing blanket, sandwich blanket, etc. The gaps between each layer shall be staggered and overlapped, and the joint shall be tight; In the laying of top sandwich blanket, "U" type fixing shall be adopted. After laying, prevent physical impact such as collision, and avoid deviation of midpoint position;

(4) Installation of insulation ceramic fiber module: After the above two layers are installed, select the position for the installation of ceramic fiber module. Insert the cold side anchor midpoint of the module into the guide rod, preliminarily fix the midpoint position, and tighten the midpoint nut by nine times after confirming that it is seamless, so as to facilitate later adjustment. After the completion, the corresponding inspection shall be carried out to ensure the flatness and beauty of the insulation work and extend the service time of the insulation layer.

Post time: Jan-03-2023