Uyilo kunye nokwakhiwa kombane wokufudumeza weentsimbi zohlobo lwentsimbi

Isishwankathelo:

Iziko lohlobo lweBell lusetyenziswa ikakhulu kunyango oluqaqambileyo kunye nobushushu, ngoko ke ziziko lobushushu obuhlukeneyo. Iqondo lobushushu lihlala phakathi kwe-650 kunye ne-1100 ℃ ubukhulu becala, kwaye litshintsha ngexesha elichazwe kwinkqubo yokufudumeza. Ngokusekelwe ekulayishweni kweentsimbi zohlobo lwentsimbi, kukho iindidi ezimbini: i-square bell-type furnace kunye ne-bell-type furnace. Imithombo yobushushu yamaziko ohlobo lwentsimbi ubukhulu becala yigesi, ilandelwa ngumbane kunye neoyile elula. Ngokubanzi, iziko lohlobo lwentsimbi lunamacandelo amathathu: isigqubuthelo sangaphandle, isiciko esingaphakathi, kunye nesitovu. Isixhobo sokutshisa sihlala sibekwe kwikhava yangaphandle efakwe kwi-thermal layer, ngelixa izixhobo zokusebenza zifakwe kwikhava yangaphakathi yokufudumeza kunye nokupholisa.

Iziko lohlobo lweBell zinokuqina kakuhle komoya, ilahleko yobushushu obuphantsi, kunye nokusebenza kakuhle kwe-thermal. Ngapha koko, abadingi mnyango wesithando somlilo okanye isixhobo sokuphakamisa kunye nezinye iindlela ezahlukeneyo zokuhambisa oomatshini, ke ngoko bonga iindleko kwaye basetyenziswa kakhulu kwiziko lobushushu lezinto zokusebenza.

Ezona mfuno zimbini zibaluleke kakhulu kwizixhobo zelinen yesithando somlilo bubunzima obulula kunye nokusebenza kakuhle kwamandla okugubungela ukufudumeza.

Iingxaki eziqhelekileyo kunye ne-refracto ekhaphukhaphu yendabukoizitena ry okanye lightweight castable Stiiructures ziquka:

1. Izinto eziphikisayo ezinobunzima obukhulu obuthile (ngokuqhelekileyo izitena ezilula ezilula eziqhelekileyo zinobunzima obuthile be-600KG / m3 okanye ngaphezulu; i-lightweight castable ine-1000 KG / m3 okanye ngaphezulu) ifuna umthwalo omkhulu kwisakhiwo sentsimbi yesigqubuthelo somlilo, ngoko zombini ukusetyenziswa kwesakhiwo sentsimbi kunye nokwandiswa kokwakhiwa kwesithando somlilo.

2. Isigqubuthelo sangaphandle esikhulu sichaphazela amandla okuphakamisa kunye nendawo yomgangatho weeworkshops zokuvelisa.

3. Isithando somlilo sohlobo lwentsimbi sisebenza kumaqondo obushushu ahlukeneyo, kwaye izitena ezikhanyelayo ezikhanyayo okanye ukukhanya okuphoswayo kunomthamo omkhulu wobushushu obuthile, i-thermal conductivity ephezulu, kunye nokusetyenziswa kwamandla okukhulu.

Nangona kunjalo, iimveliso ze-CCEWOOL ze-refractory fiber zine-conductivity ephantsi ye-thermal, ukugcinwa kobushushu obuphantsi, kunye nokuxinana kwevolumu ephantsi, ezi zezona zizathu zokusetyenziswa kwazo ngokubanzi kwizigqubuthelo zokufudumeza. Iimpawu zezi zilandelayo:

1. Uluhlu olubanzi lobushushu obusebenzayo kunye neefom ezahlukeneyo zesicelo

Ngophuhliso lwemveliso yefiber ye-ceramic ye-CCEWOOL kunye neteknoloji, iimveliso ze-CCEWOOL ze-ceramic fiber ziye zaphumelela ukulandelelana kunye nokusebenza. Ngokuphathelele ubushushu, iimveliso zinokuhlangabezana neemfuno zamaqondo obushushu ahlukeneyo ukusuka kwi-600 ℃ ukuya kwi-1500 ℃. Ngokubhekiselele kwi-morphology, iimveliso ziye zaphuhlisa ngokuthe ngcembe iintlobo zemveliso yesibini okanye imveliso enzulu evela kwikotoni yendabuko, iingubo, iimveliso ezizivayo kwiimodyuli zefiber, iibhodi, iindawo ezikhethekileyo, iphepha, iingubo zefayibha njalo njalo. Banokuhlangabezana ngokupheleleyo neemfuno zeziko loshishino lweemveliso ze-ceramic fiber kumashishini ahlukeneyo.

2. Ukuxinana kwevolumu encinci:

Ubuninzi bomthamo weemveliso ze-ceramic fiber ngokuqhelekileyo yi-96 ~ 160kg / m3, malunga ne-1/3 yezitena ezikhaphukhaphu kunye ne-1/5 ye-refractory lightweight castable. Kwisithando somlilo esandula ukuyilwa, ukusetyenziswa kweemveliso ze-ceramic fiber akukwazi nje ukugcina intsimbi, kodwa kwakhona ukwenza ukulayishwa / ukukhulula kunye nokuthutha ngokulula, ukuqhubela phambili kwi-teknoloji yesithando somlilo.

3. Umthamo omncinci wobushushu kunye nokugcinwa kobushushu:

Xa kuthelekiswa nezitena eziphikisayo kunye nezitena zokufakelwa, umthamo weemveliso ze-ceramic fiber ziphantsi kakhulu, malunga ne-1 / 14-1 / 13 yezitena eziphikisayo kunye ne-1 / 7-1 / 6 yezitena zokufakelwa. Kwisithando somlilo sohlobo lwentsimbi olusebenza ngokuphindaphindiweyo, inani elikhulu lokusetyenziswa kwe-fuel non-production-related lingagcinwa.

4. Ukwakhiwa okulula, ixesha elifutshane

Njengoko iingubo ze-ceramic fiber kunye neemodyuli zine-elasticity egqwesileyo, inani lokunyanzeliswa linokuxelwa kwangaphambili, kwaye akukho mfuneko yokushiya amajoyina okwandisa ngexesha lokwakha. Ngenxa yoko, ukwakhiwa kulula kwaye kulula, okunokugqitywa ngabasebenzi abaqeqeshiweyo abaqhelekileyo.

5. Ukusebenza ngaphandle kwe-oven

Ngokwamkela i-fiber-fiber lining, i-furnaces inokufudumala ngokukhawuleza kwiqondo lokushisa lenkqubo ukuba ayithintelwanga ngamanye amacandelo esinyithi, ephucula kakhulu ukusetyenziswa okusebenzayo kwezitofu zoshishino kunye nokunciphisa ukusetyenziswa kwe-fuel non-production-related.

6. I-thermal conductivity ephantsi kakhulu

Ifiber yeCeramic yindibaniselwano yeefiber ezinobubanzi obuyi-3-5um, ngoko ke ine-conductivity ephantsi kakhulu ye-thermal. Ngokomzekelo, xa ingubo yefayibha ye-aluminium ephezulu kunye nobuninzi be-128kg / m3 ifikelela kwi-1000 ℃ kwindawo eshushu, i-coefficient yayo yokudlulisa ubushushu yi-0.22 (W / MK kuphela).

7. Uzinzo olululo lweekhemikhali kunye nokumelana nokhukuliseko lokuhamba komoya:

Ifiber yeCeramic inokutshatyalaliswa kuphela kwi-asidi ye-phosphoric, i-hydrofluoric acid, kunye ne-alkali eshushu, kwaye izinzile kwamanye amajelo atshabalalisayo. Ukongeza, iimodyuli ze-ceramic fiber zenziwe ngokuqhubekayo ukugoqa iingubo ze-ceramic fiber kwi-compression ratio ethile. Emva kokuba umphezulu unyangwe, ukumelana nokhukuliseko lomoya kunokufikelela kwi-30m/s.

Ukwakhiwa kwesicelo sefiber ye-ceramic

Isakhiwo esiqhelekileyo selinen yesigqubuthelo sokufudumala

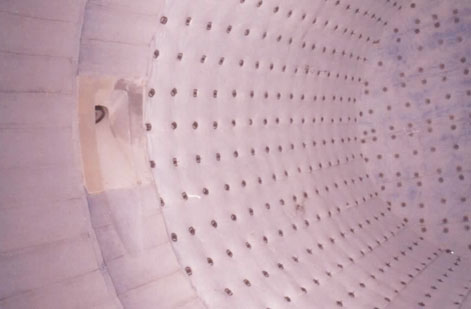

Indawo yokutshisa isigqubuthelo sokufudumala: Yamkela isakhiwo esidibeneyo se-CCEWOOL iimodyuli ze-ceramic fiber kunye neekhaphethi ze-ceramic fiber. Izinto eziphathekayo zeengubo ze-back lining zingaba yinqanaba elinye elingaphantsi kunempahla yemodyuli yomaleko wendawo eshushu. Iimodyuli zicwangciswe "kwi-battalion yamajoni" uhlobo kwaye zilungiswe ngentsimbi ye-angle okanye iimodyuli ezimisiwe.

Imodyuli yentsimbi ye-angle yeyona ndlela ilula yokufakela kunye nokusetyenziswa njengoko inesakhiwo esilula sokubambelela kwaye inokukhusela ukunyanzeliswa kwesithando somlilo ukuya kwinqanaba elikhulu.

Iindawo ezingaphezulu kwe-burner

Indlela yokubeka iingubo ze-CCEWOOL ze-ceramic fiber kwamkelwa. Ilayibhile yesithando somlilo ifuna iileya ezi-6 ukuya kwezisi-9, zilungiswe zizikrufu zentsimbi ezikwaziyo ukumelana nobushushu, izikrufu, amakhadi akhawulezayo, amakhadi ajikelezayo, kunye nezinye iindawo zokulungisa. Iingubo zefiber ze-ceramic ezinobushushu obuphezulu zisetyenziswa malunga ne-150 mm kufutshane nomphezulu oshushu, ngelixa ezinye iindawo zisebenzisa iingubo zefiber ze-ceramic zomgangatho ophantsi. Xa ubeka iingubo, amajoyina kufuneka abe ubuncinane ubuncinane be-100 mm ngaphandle. Iingubo zefiber ze-ceramic zangaphakathi zidityaniswe ngeempundu ukuququzelela ukwakhiwa, kwaye iileya ezikumphezulu oshushu zithatha indlela ethe kratya yokuqinisekisa iziphumo zokutywinwa.

Iziphumo zokusetyenziswa kwe-ceramic fiber lining

Imiphumo yesakhiwo esipheleleyo se-fiber ye-bell-type furnaces 'isikhuseli sokufudumeza sihlala silungile kakhulu. Isigqubuthelo sangaphandle esamkela esi sakhiwo asiqinisekisi kuphela ukugquma okugqwesileyo, kodwa senza kube lula ukwakhiwa; ngoko ke, sisakhiwo esitsha esinamaxabiso amakhulu okukhangisa kwi-cylindrical heat furnaces.

Ixesha lokuposa: Apr-30-2021