Ukuklama nokwakhiwa kolwelwesi lokushisisa lwezithando zohlobo lwensimbi

Uhlolojikelele:

Izithando zomlilo zohlobo lweBell zisetshenziselwa ikakhulukazi ukuthungatha okukhanyayo nokwelashwa kokushisa, ngakho zingamaziko okushisa ahlukahlukene. Izinga lokushisa lihlala phakathi kuka-650 no-1100 ℃ kakhulukazi, futhi lishintsha ngesikhathi esishiwo ohlelweni lokushisa. Ngokusekelwe ekulayishweni kwezithando zohlobo lwensimbi, kunezinhlobo ezimbili: isithando somlilo sohlobo lwensimbi yesikwele kanye nesithando somlilo esiyindilinga. Imithombo yokushisa yezithando zohlobo lwensimbi ngokuvamile igesi, ilandelwa ugesi namafutha amancane. Ngokuvamile, izithando zomlilo zohlobo lwensimbi zihlanganisa izingxenye ezintathu: ikhava yangaphandle, isembozo sangaphakathi, nesitofu. Idivayisi evuthayo ivamise ukusethwa kukhava yangaphandle ifakwe ungqimba olushisayo, kuyilapho izinto zokusebenza zifakwa kukhava yangaphakathi ukuze kufudumale futhi kupholiswe.

Izithando zohlobo lwe-Bell zinokubamba komoya okuhle, ukulahlekelwa ukushisa okuphansi, nokusebenza kahle kokushisa okuphezulu. Ngaphezu kwalokho, abadingi umnyango wesithando somlilo noma umshini wokuphakamisa nezinye izindlela zokudlulisa ngomshini, ngakho-ke zonga izindleko futhi zisetshenziswa kabanzi ezithandweni zokushisa ukushisa kwama-workpieces.

Izidingo ezimbili ezibaluleke kakhulu zezinto zokufakwa kwesithando somlilo isisindo esincane kanye nokusebenza kahle kwamandla kwezembozo zokushisa.

Izinkinga ezijwayelekile nge-refracto engasindi yendabukory izitini noma engasindi castable Stama-ructures ahlanganisa:

1. Izinto eziphikisayo ezinobukhulu obuthile obukhulu (ngokuvamile izitini eziphikisayo ezingasindi ezivamile zinesisindo esithile esingu-600KG/m3 noma ngaphezulu; okuphonswayo okungasindi kuno-1000 KG/m3 noma ngaphezulu) kudinga umthwalo omkhulu esakhiweni sensimbi sekhava yesithando somlilo, ngakho kokubili ukusetshenziswa kwesakhiwo sensimbi kanye nokutshalwa kwezimali kokwakhiwa kwesithando somlilo.

2. Ikhava yangaphandle enkulu ithinta amandla okuphakamisa kanye nendawo yaphansi yama-workshops okukhiqiza.

3. Isithando somlilo sohlobo lwensimbi sisetshenziswa emazingeni okushisa ahlukahlukene ashintshashintshayo, futhi izitini ezikhanyelayo ezikhanyelayo noma ezikwazi ukuphonswa ukukhanya zinomthamo omkhulu wokushisa othize, i-thermal conductivity ephezulu, kanye nokusetshenziswa kwamandla okukhulu.

Kodwa-ke, imikhiqizo ye-CCEWOOL refractory fiber ine-conductivity ephansi ye-thermal, isitoreji esiphansi sokushisa, kanye nokuminyana kwevolumu ephansi, okuyizizathu ezibalulekile zokusetshenziswa kwayo okubanzi kumakhava okushisa. Izici zimi kanje:

1. Ibanga lokushisa elibanzi lokusebenza kanye namafomu ezicelo ahlukahlukene

Ngokuthuthukiswa kokukhiqizwa nobuchwepheshe be-CCEWOOL ye-ceramic fiber, imikhiqizo ye-CCEWOOL ye-ceramic fiber izuze ukukhiqizwa kanye nokusebenza kahle. Mayelana nezinga lokushisa, imikhiqizo ingahlangabezana nezidingo zamazinga okushisa ahlukene asukela ku-600 ℃ kuya ku-1500 ℃. Ngokuphathelene ne-morphology, imikhiqizo iye yathuthukisa kancane kancane izinhlobonhlobo zokucubungula kwesibili noma imikhiqizo ejulile yokucubungula kusuka kukotini wendabuko, izingubo zokulala, imikhiqizo ezwakalayo kuya kumamojula we-fiber, amabhodi, izingxenye ezimise okukhethekile, iphepha, izindwangu ze-fiber nokunye. Bangakwazi ukuhlangabezana ngokugcwele nezidingo zeziko lezimboni zemikhiqizo ye-ceramic fiber ezimbonini ezihlukahlukene.

2. Ukuminyana kwevolumu encane:

Ukuminyana kwevolumu yemikhiqizo ye-ceramic fibre ngokuvamile kungu-96~160kg/m3, okungaba ngu-1/3 wezitini ezingasindi kanye no-1/5 we-lightweight refractory castable. Ngesithando somlilo esisanda kwakhiwa, ukusetshenziswa kwemikhiqizo ye-ceramic fiber akukwazi nje ukulondoloza insimbi, kodwa futhi kwenza ukulayisha / ukuthulula nokuthutha kalula, kuqhubekisele phambili inqubekelaphambili kubuchwepheshe bomlilo wezimboni.

3. Umthamo omncane wokushisa nokugcina ukushisa:

Uma kuqhathaniswa nezitini eziphikisayo nezitini zokufakelwa, amandla emikhiqizo ye-ceramic fiber aphansi kakhulu, mayelana ne-1/14-1/13 yezitini eziphikisayo kanye ne-1/7-1/6 yezitini zokufakelwa. Okwesithando somlilo esisetshenziswa ngezikhathi ezithile, inani elikhulu likaphethiloli elingahlobene nokukhiqiza lingalondolozwa.

4. Ukwakhiwa okulula, isikhathi esifushane

Njengoba izingubo zokulala ze-ceramic fiber namamojula ane-elasticity enhle kakhulu, inani lokucindezelwa lingabikezelwa, futhi asikho isidingo sokushiya amalunga okunweba ngesikhathi sokwakhiwa. Ngenxa yalokho, ukwakhiwa kulula futhi kulula, okungaqedwa ngabasebenzi abanamakhono avamile.

5. Ukusebenza ngaphandle kwehhavini

Ngokwamukela i-full-fiber lining, izithando zomlilo zingashiswa ngokushesha ekushiseni kwenqubo uma zingavinjelwe ezinye izingxenye zensimbi, okuthuthukisa kakhulu ukusetshenziswa okuphumelelayo kwezithando zezimboni futhi kunciphise ukusetshenziswa kukaphethiloli okungahlobene nokukhiqiza.

6. I-conductivity ephansi kakhulu yokushisa

I-Ceramic fiber iyinhlanganisela yezintambo ezinobubanzi obungu-3-5um, ngakho-ke ine-conductivity ephansi kakhulu yokushisa. Isibonelo, uma ingubo yokulala yefayibha ye-aluminium ephezulu enesisindo esingu-128kg/m3 ifinyelela ku-1000℃ endaweni eshisayo, i-coefficient yayo yokudlulisa ukushisa ingu-0.22(W/MK kuphela).

7. Ukuzinza okuhle kwamakhemikhali nokumelana nokuguguleka komoya:

I-Ceramic fiber ingaguguleka kuphela ku-phosphoric acid, i-hydrofluoric acid, ne-alkali eshisayo, futhi izinzile kweminye imidiya egqwalayo. Ngaphezu kwalokho, amamojula e-ceramic fiber enziwa ngokuqhubekayo ukugoqa izingubo zokulala ze-ceramic fiber ngesilinganiso esithile sokucindezela. Ngemva kokwelashwa, ukumelana nokuguguleka komoya kungafinyelela ku-30m/s.

Ukwakhiwa kwesicelo se-ceramic fiber

Isakhiwo somugqa ovamile wekhava yokushisa

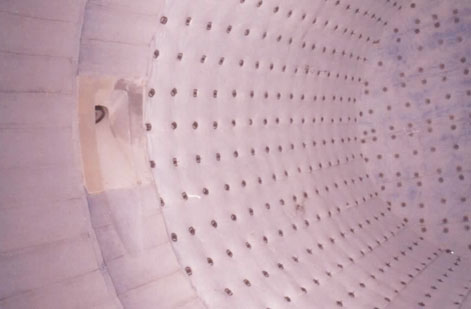

Indawo yokushisa yesembozo sokufudumeza: Yamukela ukwakheka okuyinhlanganisela yamamojula e-CCEWOOL ye-ceramic fibre kanye nokhaphethi be-ceramic fiber. Impahla yezingubo zokulala ezingemuva ingaba yibanga elilodwa eliphansi kunempahla yemojula yongqimba yendawo eshisayo. Amamojula ahlelwe ngohlobo "lwebutho lamasosha" futhi ahlanganiswe nensimbi ye-engeli noma amamojula amisiwe.

Imojuli yensimbi ye-engeli iyindlela elula yokufaka nokusetshenziswa njengoba inesakhiwo sokubambelela esilula futhi ingavikela ukucaba kolayini lwesithando ngezinga elikhulu kakhulu.

Izindawo ezingaphezulu kokushisa

Indlela yokubeka izingqimba ze-CCEWOOL ze-ceramic fiber blankets iyamukelwa. Ilayini yesithando somlilo esinezendlalelo ngokuvamile idinga izendlalelo ezingu-6 kuya kwezingu-9, ezilungiswa ngezikulufu zensimbi ezingashi, izikulufu, amakhadi asheshayo, amakhadi ajikelezayo, nezinye izingxenye zokulungisa. Izingubo zokulala zefibre ye-ceramic yezinga eliphezulu zisetshenziswa cishe ngo-150 mm eduze nendawo eshisayo, kuyilapho ezinye izingxenye zisebenzisa izingubo zokulala zefiber ye-ceramic yezinga eliphansi. Lapho ubeka izingubo zokulala, amalunga kufanele aqhelelane okungenani ngo-100 mm. Izingubo zokulala ze-ceramic fibre zangaphakathi zihlanganiswe ngezinqe ukuze kube lula ukwakhiwa, futhi izendlalelo endaweni eshisayo zithatha indlela egqagqene ukuze kuqinisekiswe imiphumela yokuvala.

Imiphumela yokusetshenziswa kwe-ceramic fiber lining

Imiphumela yesakhiwo se-fiber egcwele yekhava yokushisa yohlobo lwensimbi yokushisa ihlale mihle kakhulu. Isembozo sangaphandle esamukela lesi sakhiwo asiqinisekisi nje kuphela ukugxila okuhle kakhulu, kodwa futhi senza ukwakhiwa okulula; ngakho-ke, kuyisakhiwo esisha esinamanani amakhulu okuphromotha ama-cylindrical heat furnaces.

Isikhathi sokuthumela: Apr-30-2021