Laboratory furnaces ua lub luag haujlwm tseem ceeb hauv ntau qhov kev siv kub kub hauv kev tshawb fawb thiab kev tsim khoom lag luam. Cov cua sov no ua haujlwm ntawm qhov kub thiab txias, xav tau kev tswj xyuas meej thiab txhim khu kev qha rwb thaiv tsev. Tube furnaces thiab chamber furnaces yog ob hom, txhua tus ua haujlwm tshwj xeeb hauv cov ntsiab lus dav dav ntawm kev ua haujlwm kub. Cov kev cov nyom no cov furnaces fim muaj xws li kev tswj lub zog efficiency thiab ua tau raws li qhov kub thiab txias, ob qho tib si uas yuav cuam tshuam rau qhov zoo ntawm cov txheej txheem scientific thiab cov khoom tsim tawm.

Tube furnaces yog tsim los nrog cov duab cylindrical, feem ntau siv rau kev sim me me uas yuav tsum tau tswj qhov kub thiab txias. Cov tshuab hluav taws xob no tuaj yeem ua haujlwm horizontally, vertically, lossis ntawm ntau lub kaum ntse ntse, tso cai rau kev hloov pauv hauv chav kuaj teeb tsa. Qhov ntsuas kub ntau rau cov tub rauv yog nruab nrab ntawm 100 ° C thiab 1200 ° C, nrog qee cov qauv muaj peev xwm ncav cuag 1800 ° C. Lawv feem ntau yog siv rau kev kho cua sov, sintering, thiab tshuaj lom neeg.

Lub tshuab hluav taws xob tus qauv tsim los rau cov chaw kuaj mob muaj cov programmable controllers nrog ntau ntu, muab kev tswj qhov kub thiab txias. Cov xaim cua sov feem ntau raug mob nyob ib ncig ntawm lub raj, tso cai rau kom muaj cua sov sai thiab sib npaug ntawm qhov kub thiab txias.

Chamber furnaces feem ntau yog siv rau cov ntawv loj dua, muab cov cua sov dav dav thiab cov cua kub ntau sab rau cov cua sov sib xws thoob plaws hauv lub chamber. Cov cua sov no tuaj yeem ncav cuag qhov kub txog li 1800 ° C, ua rau lawv haum rau annealing, tempering, thiab lwm yam txheej txheem kub. Lub chamber rauv ua haujlwm ntawm qhov kub siab tshaj plaws ntawm 1200 ° C thiab nta tsib sab cua sov rau txawm tias qhov kub thiab txias.

Kev sib tw hauv Kev Ua Haujlwm Kub Kub

Laboratory furnaces xav tau kev rwb thaiv tsev zoo los tswj lub zog ua haujlwm thiab ua kom muaj kev nyab xeeb ntawm cov khoom siv hluav taws xob. Kev rwb thaiv tsev tsis txaus ua rau muaj kev kub ntxhov loj, qhov kub tsis sib xws, thiab kev siv hluav taws xob ntau ntxiv. Qhov no, nyob rau hauv lem, tuaj yeem cuam tshuam qhov zoo ntawm cov txheej txheem uas tau ua thiab ua kom luv luv lub neej ntawm cov khoom siv hluav taws xob.

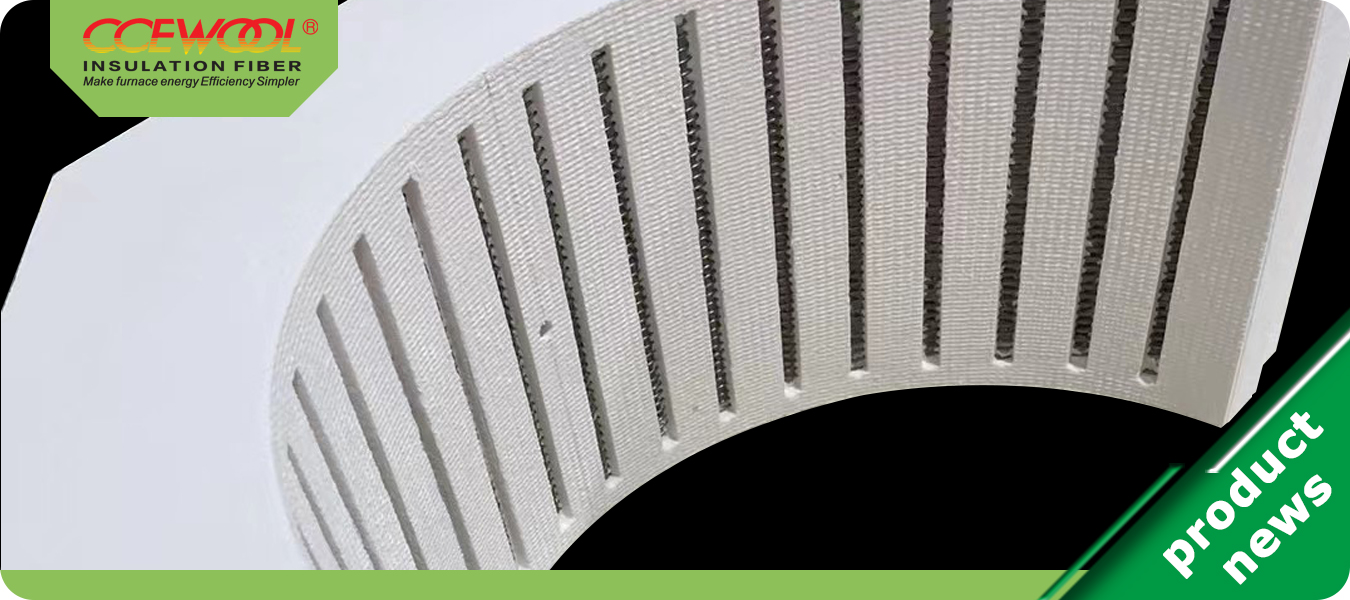

CCEWOOL® Nqus Plua Plav tsim Refractory Fiber Shapes

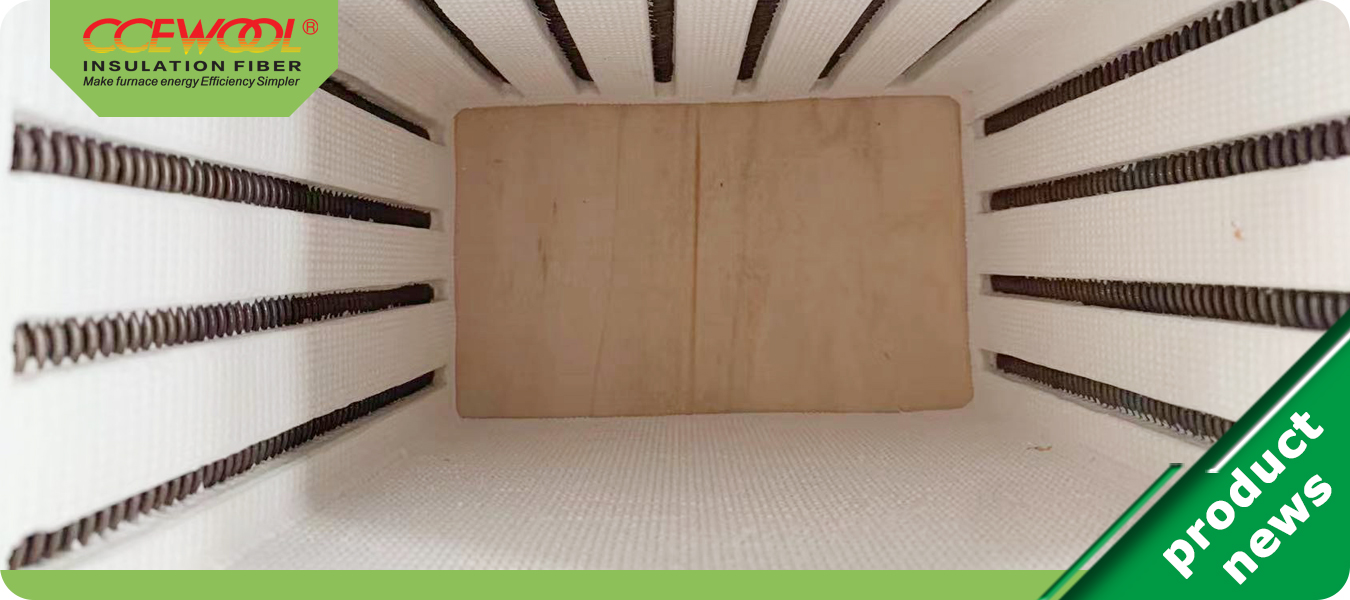

CCEWOOL® Nqus Plua Plav tsim Refractory Fiber Shapesyog tsim los daws cov teeb meem kev thaiv hluav taws xob uas tau ntsib los ntawm cov chaw kuaj sim. Cov duab no tuaj yeem tiv taus qhov kub thiab txias, nrog kev tiv thaiv txog 1800 ° C, ua rau lawv tsim nyog rau kev thov xws li lub tshuab nqus tsev annealing, hardening, thiab brazing. Lub peev xwm los kho CCEWOOL® cov duab tso cai rau lawv kom haum raws li cov neeg siv khoom xav tau, tsom mus rau cov duab thiab kev teeb tsa ntawm cov hlau resistant. Qhov no ua kom tsis muaj kev sib koom ua ke rau hauv cov qauv tsim hluav taws xob uas twb muaj lawm, suav nrog cov khoom siv hluav taws xob, chamber furnaces, hluav taws xob txuas ntxiv, thiab lwm yam.

Ntxiv nrog rau cov khoom siv fiber ntau ceramic, CCEWOOL® muaj cov khoom siv polysilicon fiber ntau tiv thaiv cov duab rau cov ntawv thov uas yuav tsum tau ua kom sov siab dua. Cov khoom siv siab heev no muab cov rwb thaiv tsev zoo tshaj plaws, ua rau tsawg kawg thermal poob thiab txhim kho lub zog efficiency. Kev ruaj ntseg ntawm cov ntaub ntawv no tiv thaiv deformation thiab tswj thermal kev ncaj ncees thaum lub sijhawm ua haujlwm kub, ua kom ntev lub neej ntawm cov khoom siv hluav taws xob.

Yooj yim ntawm installation thiab tu

CCEWOOL® Vacuum Formed Refractory Fiber Shapes yog tsim los rau kev yooj yim installation, uas yog ib qho tseem ceeb nyob rau hauv lub chaw soj nstuam furnaces qhov chaw downtime yuav cuam tshuam rau productivity. Qhov kev xaiv los siv lub tshuab nqus tsev-forming hardener lossis refractory mortar muab kev tiv thaiv ntxiv, ua kom ruaj khov hauv kev lag luam nruj. Cov txheej txheem kev teeb tsa yooj yim no tso cai rau lub tshuab hluav taws xob rov qab mus ua haujlwm sai tom qab kev kho lossis kho, txo qis sijhawm thiab cov nqi ua haujlwm.

Xaus

Laboratory furnaces yog lub hauv paus rau ntau qhov kev siv kub-kub, thiab lawv cov kev ua tau zoo nyob ntawm kev tswj qhov kub thiab txias thiab rwb thaiv tsev zoo. CCEWOOL® Vacuum Formed Refractory Fiber Shapes muab cov kev daws teeb meem zoo, muab kev tiv thaiv kub kub, kev hloov kho, thiab kev siv hluav taws xob. Los ntawm kev sib koom ua ke cov duab no rau hauv chav kuaj qhov cub, koj tuaj yeem ua tiav qhov kev ua tau zoo, txo qis cua sov, thiab tswj kom muaj qhov chaw sov sov. Qhov no ua rau cov txheej txheem kev lag luam muaj txiaj ntsig zoo dua thiab txhim khu kev qha, ua rau txo cov nqi khiav lag luam thiab txuas ntxiv lub neej ntawm cov khoom siv hluav taws xob.

Post lub sij hawm: Apr-26-2024