Ceramic fiber yog cov khoom siv thermal rwb thaiv tsev ib txwm siv dav hauv kev lag luam xws li metallurgy, machinery, electronics, ceramics, iav, tshuaj, tsheb, kev tsim kho, lub teeb kev lag luam, tub rog shipbuilding, thiab aerospace.Raws li cov qauv thiab muaj pes tsawg leeg, ceramic fiber yuav categorized rau hauv loj hom: iav xeev (amorphous) fibers (polycrystalline) fibers thiab polycrystalline.

1.Cov txheej txheem ntau lawm rau iav xeev fibers.

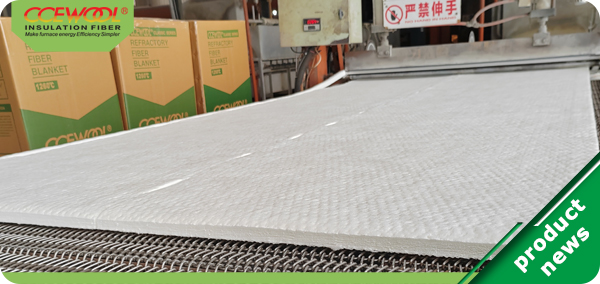

Txoj kev tsim cov iav ceramic fibers cuam tshuam cov ntaub ntawv raw hauv lub qhov cub hluav taws xob. Cov khoom kub kub molten ntws tawm los ntawm lub qhov hluav taws xob mus rau qhov kub ceev tig nruas ntawm ntau cov menyuam centrifuge. Lub zog centrifugal ntawm lub nruas rotating ua rau cov khoom kub kub molten rau hauv cov khoom siv fiber ntau. Cov khoom kub-kub molten kuj tuaj yeem ua rau cov khoom siv fiber ntau los ntawm kev raug tshuab nrog kev kub ceev airflow.

2 Polycrystalline fiber ntau txoj kev

Muaj ob txoj kev tsim khoom ntawm polycrystallineceramic fibers: colloid method thiab precursor method.

Txoj kev Colloidal: ua rau cov kua ntsev uas muaj kuab lom, silicon ntsev, thiab lwm yam rau hauv cov tshuaj colloidal nrog ib qho viscosity, thiab cov kwj dej yog tsim rau hauv fibers los ntawm cua tshuab los ntawm compressed cua los yog spun los ntawm centrifugal disk, thiab ces hloov mus rau hauv aluminium-silicon oxide crystals fibers los ntawm high-temperature tshav kub kho.

Cov txheej txheem ua ntej: Ua cov hmoov txhuas ntsev thiab silicon ntsev rau hauv cov tshuaj colloidal nrog cov viscosity, nqus cov tshuaj colloidal tusyees nrog lub precursor (nthuav dav cov organic fiber), thiab tom qab ntawd ua cov kev kho cua sov kom hloov mus rau txhuas-silicon oxide crystal fiber.

Post lub sij hawm: Aug-07-2023